Straight forward question. Was it possible for Steam Driven vessels, Tugs especially, to have Variable Pitch propellors??.

Variable Pitch Propellors.

OLD STRAWBERRY

Discussion starter

1,132 posts

·

Joined 2006

- Add to quote Only show this user

Straight forward question. Was it possible for Steam Driven vessels, Tugs especially, to have Variable Pitch propellors??.

52 posts

·

Joined 2006

The controllable/variable pitch propeller system was operated hydraulically with an electric pump providing the power, so was independent of the main propulsion

system be it steam or motor, I was Master for several years with twin c.p.p propellers and found that if you used zero pitch you immediately lost steerage control because of the now spinning flat disc immediately aft of the rudder, a setting of 2 ahead would immediately restore steering control

system be it steam or motor, I was Master for several years with twin c.p.p propellers and found that if you used zero pitch you immediately lost steerage control because of the now spinning flat disc immediately aft of the rudder, a setting of 2 ahead would immediately restore steering control

250 posts

·

Joined 2008

Any propellor working aft of a rudder is doing a very good job. Not only hydraulics but spring loaded hubs could be used manually - usually in an emergency but early designs do exist where mechanical systems were possible.

3,401 posts

·

Joined 2015

Hundested vp propellers with mechanical control were popular with Scandinavian fishing vessels and workboats. I imagine they could have been used with steam engines as they were commonly installed on vessels with slow revving diesel or semi diesel engines. We had a pair fitted to the auxiliary ketch Orcella, but these were set to be fully feathered to reduce drag when under pure sail. The shafts had locking devices fitted to prevent any rotation when the props were feathered. When resetting the pitch, a fairly rudimentary scale gave an indication of what angle the blades were, and a pyrometer on each engine indicated the load. (She was twin screw). After arrival at her home in Seattle, modifications using aircraft flap motors and angle indicators were installed to improve the ease of changing the pitch.

OLD STRAWBERRY

Discussion starter

1,132 posts

·

Joined 2006

Thanks all. Question arose whilst chatting about old Naval/PAS Steam tugs of the "Samson" Class. Evidently some did and some didn't. Thanks for the info' Boys.

2,759 posts

·

Joined 2005

I sailed a boat on the "Lakes" that had been converted from a turbine engine to a direct drive diesel and it was a nightmare to steer.

Before the turbine never stopped the propeller always turning and a wash going over the rudder which did allow some steerage way at stopped.

When the diesel stopped all wash then stopped over the rudder and it had next to no effect as it was too small in these conditions.

With variable pitch propellers you had infinite control and could have early zero pitch and still steer.

Before the turbine never stopped the propeller always turning and a wash going over the rudder which did allow some steerage way at stopped.

When the diesel stopped all wash then stopped over the rudder and it had next to no effect as it was too small in these conditions.

With variable pitch propellers you had infinite control and could have early zero pitch and still steer.

5,027 posts

·

Joined 2005

A bit of a misnomer here ; almost all propellers have a variable pitch unless is is an Archimedes screw .

What is being discussed is a controllable pitch propeller ; two different things .

A controllable pitch prop also has a variable pitch .

Not knowing the difference is a good way to fail Chiefs orals . Derek

What is being discussed is a controllable pitch propeller ; two different things .

A controllable pitch prop also has a variable pitch .

Not knowing the difference is a good way to fail Chiefs orals . Derek

11,483 posts

·

Joined 2009

A point of much discussion as it can be argued that while different sections of a blade do indeed have different pitches the prop overall has just a single pitch and that a controllable pitch propeller blade is the same but the overall pitch can be varied. Basically semantics . I happily use both terms interchangeably though I never use the term VPP

109 posts

·

Joined 2008

Dive Support Vessel " Uncle John " had eight variable pitch propellors , two for ahead and astern and six for sideways , electricaly driven with 6kv motors from five V18 Hedemora diesel driven alternators . These to serve the dynamic positioning system . It is now almost 40 years on and my memory is not absolute on this and I'm not sure whether they were spring loaded one way or the other , but what did happen on hydraulic failure was the propellor would go creep to full pitch in whatever direction it was in at the time of the failure . This led to very interesting situations with divers on the sea bed and the vessel positioned 15 - 20 metres of a platform . The vessel would start to rotate like a merry go round , other propellors would respond , more load

on the board , standby engines would start and synchronise automaticaly

adding more power for the system to play with . Dive control pulling the divers back to the bell and then retrieving the bell and the operators in the DP control restoring order . There were situations that had not been considered , fortunately , to my memory at least , order was always restored .

on the board , standby engines would start and synchronise automaticaly

adding more power for the system to play with . Dive control pulling the divers back to the bell and then retrieving the bell and the operators in the DP control restoring order . There were situations that had not been considered , fortunately , to my memory at least , order was always restored .

1,964 posts

·

Joined 2008

Original variable pitch propellers fail safe was ahead (get you home) until the MANCHESTER COURAGE(photos in Gallery)rammed the lock gates in the Manchester sship canal and emptied it.

265 posts

·

Joined 2009

On the KaMeWa CPPs in P&O Southern Ferries 'Eagle' and 'Dragon' it was possible to jack the pitch into 'ahead' as a get you home. We discovered in 'Eagle' that if you neglected to remove a certain vent plug when testing the system you could stretch the control rod inside the shaft by 4 inches, thus enabling the propeller to only run at full astern pitch!

988 posts

·

Joined 2015

Due to the large hub of a CPP you do lose thrust as compared to a fixed pitch propellor. So for an ocean going ship a fp prop is better, but for a short sea trader with a lot of docking, such as cross channel ferries and perhaps cruise ships (that are glorified coasters and don't go deep sea as opposed to a passenger liner).

During the 1988 IMareEng IMASS conference on Cruise Ships there was a speaker from KameWa extolling the virtues of CPP, in the Q&A session quite a lively debate ensued, I suppose similar to the sail/steam debate at the time.

It is a case of using the correct prop for the duties of the vessel by lifetime costing of both systems.

Whilst serving my apprenticeship on Hull Fish Dock in 68-73 , I watched the overhaul of CP props and yes there was a darn great spring (similar to those fitted on early B&W exh valve engines about 18"diameter), which put the pitch into ahead in case of hydro-mechanical failure.

The industry was changing from steam sidewinders to diesel and also to diesel Stern Freezers/factory ships which were fitted with the CP prop.

A vessel with a CP prop does require a complicated governor system, a steam recip engine on a tug probably is not fitted with governor, just a hand operated flap valve inthe HP steam line. Though CPP is possible, it is a rather complicated system on a basic engine that requires a lot of hands on to operate.

A tug requiring a high bollard pull needs an efficient prop with a fixed pitch does.

Just to go off topic slightly.

The late United Towing Company from Hull, bought an ocean going tug (Statesman) from the Japanese (I think), built by the US. This had twin CP props(or was it quad) with reduction gearboxes driven by twin v- bank engines (about 18 cylinders per engine). It also had several/countless v- bank diesel alternators. The engines I believe were Detroit Diesels or GM of two different sizes and typical of US thinking more cubic inches the better, hence so many engines. We would have fitted large slow revving 4 strokes not all these little screamers with goodness knows how many units. Cylinder heads were aluminium, though considering the number you would have to hump about just as well.

She was the most powerful tug in the world at the time about 1972. She had good lines and the bridge/ accomodation looked like a liner rather than a boxy tug.

I may have put the thumbnail image up on the tug section, showing her on speed trials in the Humber after her complete overhaul by all the ship repair companies in Hull. We all got a slice of the cake.

During the 1988 IMareEng IMASS conference on Cruise Ships there was a speaker from KameWa extolling the virtues of CPP, in the Q&A session quite a lively debate ensued, I suppose similar to the sail/steam debate at the time.

It is a case of using the correct prop for the duties of the vessel by lifetime costing of both systems.

Whilst serving my apprenticeship on Hull Fish Dock in 68-73 , I watched the overhaul of CP props and yes there was a darn great spring (similar to those fitted on early B&W exh valve engines about 18"diameter), which put the pitch into ahead in case of hydro-mechanical failure.

The industry was changing from steam sidewinders to diesel and also to diesel Stern Freezers/factory ships which were fitted with the CP prop.

A vessel with a CP prop does require a complicated governor system, a steam recip engine on a tug probably is not fitted with governor, just a hand operated flap valve inthe HP steam line. Though CPP is possible, it is a rather complicated system on a basic engine that requires a lot of hands on to operate.

A tug requiring a high bollard pull needs an efficient prop with a fixed pitch does.

Just to go off topic slightly.

The late United Towing Company from Hull, bought an ocean going tug (Statesman) from the Japanese (I think), built by the US. This had twin CP props(or was it quad) with reduction gearboxes driven by twin v- bank engines (about 18 cylinders per engine). It also had several/countless v- bank diesel alternators. The engines I believe were Detroit Diesels or GM of two different sizes and typical of US thinking more cubic inches the better, hence so many engines. We would have fitted large slow revving 4 strokes not all these little screamers with goodness knows how many units. Cylinder heads were aluminium, though considering the number you would have to hump about just as well.

She was the most powerful tug in the world at the time about 1972. She had good lines and the bridge/ accomodation looked like a liner rather than a boxy tug.

I may have put the thumbnail image up on the tug section, showing her on speed trials in the Humber after her complete overhaul by all the ship repair companies in Hull. We all got a slice of the cake.

250 posts

·

Joined 2008

The UTC Tug you mention was "Statesman" (ex "Alice Moran"), certainly one of the most powerful tugs in the world at the time but "Lloydsman" , built in 1970 was larger and a little more powerful. Both of them were beautiful ships.

Howard

Howard

109 posts

·

Joined 2008

KaMeWa Side Thrusters DSV Uncle John

Feed back , to give actual pitch position from the hub mechanism to the Hunting Mechanism on the hydraulic control unit , was from a bearing in the centre of the rotating crosshead that moved the blades , the bearing was

some 50mm od X 20mm id , probable cost about £15.00 . In the centre of the bearing was a stationary pin 20mm dia with a roller chain connected to it.

The chain passed over two or three sprockets to another pin that ran in seals

to exit the the body of the thruster . A further length of chain then drove the

hunting mechanism and potentiometer . The chain both internal and external

to the hub , from memory , being a similar size to the drive chain of a bicycle .

Failure of the £15.00 hub centre bearing resulted in the stationary pin rotating which then snapped the chain . Thus no feedback and no control . This happened on two of the thrusters , one a tunnel thruster in one of the hulls

which was permanently submerged , the other in a nozzle thruster which was

exposed at transit draught . This resulted in a trip off the field to Yell Sound in

the Shetlands where the onboard crew stripped the hub and rebuilt it . Hull freeboard at the time was at most 12" and at times water up to your waist. A successful repair was carried out .

Feed back , to give actual pitch position from the hub mechanism to the Hunting Mechanism on the hydraulic control unit , was from a bearing in the centre of the rotating crosshead that moved the blades , the bearing was

some 50mm od X 20mm id , probable cost about £15.00 . In the centre of the bearing was a stationary pin 20mm dia with a roller chain connected to it.

The chain passed over two or three sprockets to another pin that ran in seals

to exit the the body of the thruster . A further length of chain then drove the

hunting mechanism and potentiometer . The chain both internal and external

to the hub , from memory , being a similar size to the drive chain of a bicycle .

Failure of the £15.00 hub centre bearing resulted in the stationary pin rotating which then snapped the chain . Thus no feedback and no control . This happened on two of the thrusters , one a tunnel thruster in one of the hulls

which was permanently submerged , the other in a nozzle thruster which was

exposed at transit draught . This resulted in a trip off the field to Yell Sound in

the Shetlands where the onboard crew stripped the hub and rebuilt it . Hull freeboard at the time was at most 12" and at times water up to your waist. A successful repair was carried out .

11,674 posts

·

Joined 2006

I 'felt' that date much too late and related to aircraft developments. One can Google a reference to a variable pitch propeller of 1849 by Griffiths and wonder if another member can do better.

I am also sure that the technique was used in small boats for altering direction (presumably after the introduction of the internal combustion engine as reciprocating steam was easy enough to reverse on the prime mover).

Altering blade angles, 'on the move' as it were, would not have taken the marine fraternity by much surprise as later paddle technology had several variations on the theme.

I am also sure that the technique was used in small boats for altering direction (presumably after the introduction of the internal combustion engine as reciprocating steam was easy enough to reverse on the prime mover).

Altering blade angles, 'on the move' as it were, would not have taken the marine fraternity by much surprise as later paddle technology had several variations on the theme.

669 posts

·

Joined 2013

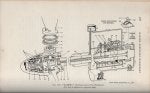

KaMeWa V.P.P.

From memory the only problem we had was the forming of microbes in the hydraulic oil which rendered the system inoperable. I think it was a Shell oil but can't remember type or grade. The main spring set the blades to full ahead thus giving some control. Having a bow thruster help with manoeuvring.

The diagrams have some information of the system.

From memory the only problem we had was the forming of microbes in the hydraulic oil which rendered the system inoperable. I think it was a Shell oil but can't remember type or grade. The main spring set the blades to full ahead thus giving some control. Having a bow thruster help with manoeuvring.

The diagrams have some information of the system.

Attachments

-

493.3 KB Views: 137

-

396.1 KB Views: 221

-

446.2 KB Views: 144

988 posts

·

Joined 2015

Thanks Bill,

Allways wondered how these worked, even though I have seen a few stripped down in the drydock. I was probably a bit young at the time to ask or understand as a 17 year old apprentice. The fitters wouldn't have known, we always had a makers man down to supervise and do critical parts.

Most of the CPP 's were Stone Manganese Marine, but same design.

I remember once they opened one up and boss on which one of the blades was attached had cracked in the step section , ie at the base of the small diameter boss.

Now if that blade would have come off at speed it would have spoiled somebodies day and probably holed the hull. My guess they probably caught a bit of ice.

Stern trawler up in Greenland or Barents sea.

Allways wondered how these worked, even though I have seen a few stripped down in the drydock. I was probably a bit young at the time to ask or understand as a 17 year old apprentice. The fitters wouldn't have known, we always had a makers man down to supervise and do critical parts.

Most of the CPP 's were Stone Manganese Marine, but same design.

I remember once they opened one up and boss on which one of the blades was attached had cracked in the step section , ie at the base of the small diameter boss.

Now if that blade would have come off at speed it would have spoiled somebodies day and probably holed the hull. My guess they probably caught a bit of ice.

Stern trawler up in Greenland or Barents sea.

250 posts

·

Joined 2008

On a similar vein - Houston Ship Canal. Making a turn in darkness to move back down when we encountered a loose channel buoy and a subsequent amount of heavy duty chain. Single screw KaMeWa but twin engine Peilsticks. We lost one blade due to fractured boss and when we drydocked it became obvious the actual hub was also damaged beyond repair.. At the time we were motoring (sic) on one engine as the other one was stripped down for removal of the main crankshaft due to a crankcase explosion leaving Chittagong. I do not know what I did with my spare time on that ship. (K)

988 posts

·

Joined 2015

Hmm,

Some people get all the fun!

Pielsticks, goodness me what had you done to deserve being landed with those.

As one old chestnut says, "Never join a ship with an engine begining with "P", such as Paxmans, Pielsticks and PDoxfords".

They wouldn't know they are born the engineers of today on some of the engines and situations we had to put up with in our day.

Some people get all the fun!

Pielsticks, goodness me what had you done to deserve being landed with those.

As one old chestnut says, "Never join a ship with an engine begining with "P", such as Paxmans, Pielsticks and PDoxfords".

They wouldn't know they are born the engineers of today on some of the engines and situations we had to put up with in our day.

250 posts

·

Joined 2008

Interesting work all the same. Once the decisions are made re what needs doing then a plan falls into place and we work through it. Some satisfaction in overcoming the logistics and being able to run the plant as close to what it should do. Albeit with Peilsticks the wear rates were so bad that good times never lasted long. Character forming??? There were worse times to come with Russian designed , Yugoslav built B&W and more V18 Peilsticks. But that is another story as they say

669 posts

·

Joined 2013

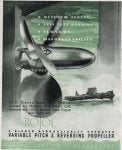

This has turned into a very interesting discussion started by " Old Strawberry."

As KaMeWa is the only type I have had any experience of, I was surprised to come across an advert while browsing in The Motor Ship of July 1947. It was for a Rotol variable pitch & reversing propeller for a small harbour tug, will down load it.

I have also been searching the internet for information on Rotol Ltd Gloucester. The only thing seemed to be the aviation industry, no marine side and then came across this post. Saunders Roe (Anglesey) MTB 539 it contained mention of a Rotol propeller. This is one for the R.N. boys but really worth a look. dave-mills.yolasite.com/saunders-roe-mtb.php

Bill

As KaMeWa is the only type I have had any experience of, I was surprised to come across an advert while browsing in The Motor Ship of July 1947. It was for a Rotol variable pitch & reversing propeller for a small harbour tug, will down load it.

I have also been searching the internet for information on Rotol Ltd Gloucester. The only thing seemed to be the aviation industry, no marine side and then came across this post. Saunders Roe (Anglesey) MTB 539 it contained mention of a Rotol propeller. This is one for the R.N. boys but really worth a look. dave-mills.yolasite.com/saunders-roe-mtb.php

Bill

Attachments

-

280 KB Views: 162

109 posts

·

Joined 2008

Variable Pitch

We all know exactly what is being refered to as " Variable Pitch " in

this thread .

We all know exactly what is being refered to as " Variable Pitch " in

this thread .

5,027 posts

·

Joined 2005

My last trip on a Tanker was Lustrous Dubai to Stendngsond ; Johnny was the super who met us there . He took me out for a very nice dinner before I flew home and all the conversation was about the turbo chargers . At the end I think I had him convinced that a retrofit to Brown Boveri would solve a lot of the charter speed problems .

The next time I saw him was when I resigned to emigrate to Canada ; he did his best to try and make me change my mind and again provided a very nice dinner . No regrets ; who was to know then what was about to happen to the Brocks fleet ?

I always got on well with John ; he was a good engineer . Last I heard of him he was a "Big Wig " in the Highlands and Islands development board .

Cheers Derek

The next time I saw him was when I resigned to emigrate to Canada ; he did his best to try and make me change my mind and again provided a very nice dinner . No regrets ; who was to know then what was about to happen to the Brocks fleet ?

I always got on well with John ; he was a good engineer . Last I heard of him he was a "Big Wig " in the Highlands and Islands development board .

Cheers Derek

42 posts

·

Joined 2014

To clarify, Controllable Pitch Propellers are those (the clue's in the name) whose Blade Pitch can be Mechanically altered (controlled) whilst underway. The term Variable Pitch refers to those Props whose Blade Pitch can be adjusted, but not during operation, i.e the individual blades can be rotated on the hub to 'Fine Tune', probably no more than a few degrees, in order to get maximum efficiency (in dock or alongside only). Even with today's complex computer modelling, nothing can predict the exact performance of the 'Real Deal' once installed.

I believe the Props for the two new RN Carriers have this feature.

Regarding Emergency situations, the RN CPP on the Type 21, 22, 42 classes had a feature that, in the case of of a Hydraulic failure (blown seals somewhere), the pitch could be altered and locked in a usable state to get home. This involved mechanically turning the Oil Transfer Tubes running from the Oil Transfer Box on the Gearbox to the Hub, which in turn would move the actuator and rotate the blades. In practice though, there was a huge amount of stress and twisting of the Tubes and use of this was virtually forbidden in Peacetime unless in extreme situations. Better to get a tow rather than risk severe damage to the mechanism.

I believe the Props for the two new RN Carriers have this feature.

Regarding Emergency situations, the RN CPP on the Type 21, 22, 42 classes had a feature that, in the case of of a Hydraulic failure (blown seals somewhere), the pitch could be altered and locked in a usable state to get home. This involved mechanically turning the Oil Transfer Tubes running from the Oil Transfer Box on the Gearbox to the Hub, which in turn would move the actuator and rotate the blades. In practice though, there was a huge amount of stress and twisting of the Tubes and use of this was virtually forbidden in Peacetime unless in extreme situations. Better to get a tow rather than risk severe damage to the mechanism.

11,674 posts

·

Joined 2006

#38. The last (and only) time I had anything to do with a vessel with such facilities it was a matter of fairly strict 'convention' they be referred to as adjustable pitch. Controllable and variable are in common usage for the 'normal' animal.

Should anyone design a propeller with a variable attribute similar to the meteorological meaning in "winds light to variable" or indeed a method of making the wind controllable as with a "controllable pitch propeller" I have no doubt the semantic distinction would become more important.

If this is a P&Oh or The Cunard versus the rest which is to be the posh description and which the peasant?

Should anyone design a propeller with a variable attribute similar to the meteorological meaning in "winds light to variable" or indeed a method of making the wind controllable as with a "controllable pitch propeller" I have no doubt the semantic distinction would become more important.

If this is a P&Oh or The Cunard versus the rest which is to be the posh description and which the peasant?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 1.1M

- members

- 137K

- Since

- 2004

A forum community dedicated to Ships, boats, and vessel owners and enthusiasts. Come join the discussion about crew logs, maritime history, shipping lines, shipwrecks, cruise ships, weather, and more!